The crown,although it plays a supporting role, is indispensable in the functions of a wristwatch and often serves as the finishing touch in design.

As an accessory on the exterior of a wristwatch that needs to be movable and is connected to the internal structure, the waterproof performance of the crown directly affects the overall waterproof performance of the wristwatch.

The waterproof structure and performance of the wristwatch as a whole have been described in detail in posts on relevant forums, so I won’t go into details here. I have been engaged in work related to finished watches for many years, and now I’d like to share what I know.

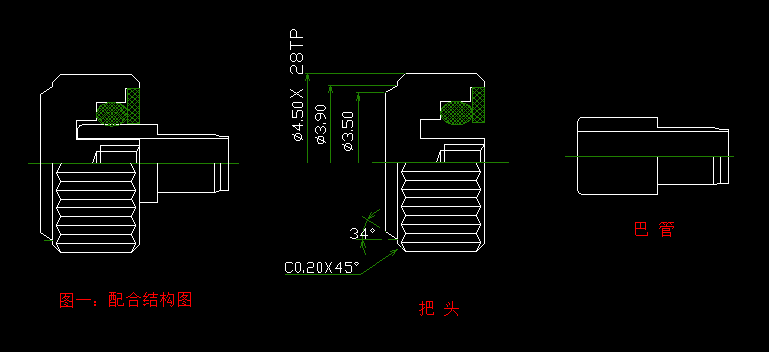

The simplest structure is the single waterproof ring structure. There is a waterproof ring hidden inside the crown, and an external steel sheet is riveted and covered on it. The whole thing cooperates with the stem tube that is pressed into the watch case.

Of course, it can also be the other way around. The position of the waterproof ring can be placed on the stem tube, and a groove for accommodating the waterproof ring can be hooked on the inner wall of the stem tube. However, this structure will increase the production cost to some extent. Moreover, since the space for accommodating the waterproof ring is smaller, resulting in less contact surface, its waterproof performance will be worse than that of the previous method, so it is not very common.

The single waterproof ring structure can achieve a waterproof function of 1 – 3 ATM by adjusting the fitting dimensions, the material and specifications of the waterproof ring, as well as the manufacturing process.

The material of the waterproof ring is usually silica gel. Since the crown needs to be pulled and rotated, the elastic size of the waterproof ring must be controlled within a certain range. If it’s too loose, the waterproof effect will be poor, and if it’s too tight, it will affect its functions.

To improve the waterproof performance of the crown, the most effective method is to increase the number of waterproof rings. According to the positions of the two waterproof rings, there are three waterproof structures: the inner double waterproof ring crown, the outer double waterproof ring crown, and the inner and outer double waterproof structure.

All of these three structures can achieve a waterproof function of 3 – 10 ATM, among which the inner and outer double waterproof structure has the best performance.

The double waterproof structure extends out from the stem core and is shaped like the letter “T”. In the industry, this kind of crown is also called the “T-shaped” crown.

There is also the familiar screw-down (lockable) crown.

The waterproof ability of the screw-down crown can reach at least 10 ATM (100 meters) or more. Two waterproof rings can be set inside the stem tube. The most crucial point is that an annular flat waterproof ring is placed in the gap where the bottom of the crown contacts the stem tube. When the crown is screwed in, it presses against the waterproof ring, achieving extremely strong waterproof performance.

Even when the crown is unscrewed for time adjustment or winding, due to the function of the waterproof ring inside the stem tube, it can still have a waterproof performance of 1 – 3 ATM.

I haven’t drawn for many years, so my drawing skills are a bit rusty. Even though I modified the production drawings obtained from my friends, they still look a bit ugly. After all, I’m not a professional draftsman. I hope watch enthusiasts can understand this.

The above are my personal experiences and insights. If there are any incorrect points, welcome watch enthusiasts to communicate and correct them. Thank you!

The Waterproof Performance of Watch Crowns: An In-depth Exploration

The crown, a seemingly unassuming yet crucial component of a wristwatch, plays a significant role in determining the overall waterproof integrity of the timepiece. Its waterproof performance is a complex and multi-faceted aspect that demands careful consideration.

At the most basic level, we have the single waterproof ring structure. In this configuration, a single waterproof ring is nestled within the crown. An external steel sheet is then riveted over it, creating a barrier against water ingress. This assembly interfaces with the stem tube that is press-fitted into the watch case. The waterproof ring, typically made of silicone, is carefully calibrated in terms of its elastic dimensions. It must strike a delicate balance: if it is too loose, water can seep through, compromising the watch’s waterproof capabilities; if it is too tight, it can impede the proper functioning of the crown, such as smooth pulling and rotating actions. Through meticulous adjustments of the fitting dimensions, the specific material and specifications of the waterproof ring, and the manufacturing process, this single waterproof ring structure can generally achieve a waterproof rating of 1 – 3 ATM.

However, to enhance the waterproof performance, the addition of more waterproof rings becomes necessary. There are three main types of double waterproof ring structures based on the positioning of the rings: the inner double waterproof ring crown, the outer double waterproof ring crown, and the inner and outer double waterproof structure.

The inner double waterproof ring crown has two waterproof rings positioned within the crown itself. This design offers increased protection compared to the single ring structure and can typically achieve a waterproof rating of 3 – 10 ATM. The outer double waterproof ring crown, on the other hand, has the two waterproof rings located on the outside of the crown in a specific arrangement that also contributes to better water resistance within the 3 – 10 ATM range.

The inner and outer double waterproof structure is considered the most effective among these. It features a double waterproof structure that extends out from the stem core, resembling the letter “T”, which is why it is also known as the “T-shaped” crown in the industry. This design not only provides multiple layers of protection but also optimizes the interaction between the crown and the stem tube to enhance the overall waterproof performance, allowing it to reach the upper end of the 3 – 10 ATM range.

Finally, the screw-down (lockable) crown represents a pinnacle of waterproof technology. It is capable of withstanding water pressures of at least 10 ATM (equivalent to 100 meters of water depth). Inside the stem tube, two waterproof rings are strategically placed. Moreover, a crucial annular flat waterproof ring is situated in the gap where the bottom of the crown contacts the stem tube. When the crown is screwed in, it exerts pressure on this ring, creating an extremely tight seal. Even when the crown is unscrewed for essential functions like time adjustment or winding, the presence of the waterproof ring inside the stem tube ensures a residual waterproof performance of 1 – 3 ATM, minimizing the risk of water damage during these operations.

In conclusion, the waterproof performance of watch crowns is a vital aspect that directly impacts the durability and reliability of a wristwatch in various environmental conditions. Manufacturers must carefully engineer and select the appropriate waterproofing mechanisms to meet the desired standards and protect the internal components of the watch from water-related damage.